Optimum 918DH Tool Test Results that You Need to See

Balancing productivity, tool life, and cost efficiency is a constant challenge, and when one falters, the entire operation feels the impact. In the fast-paced world of semiconductor manufacturing, precision isn't just important—it's everything.

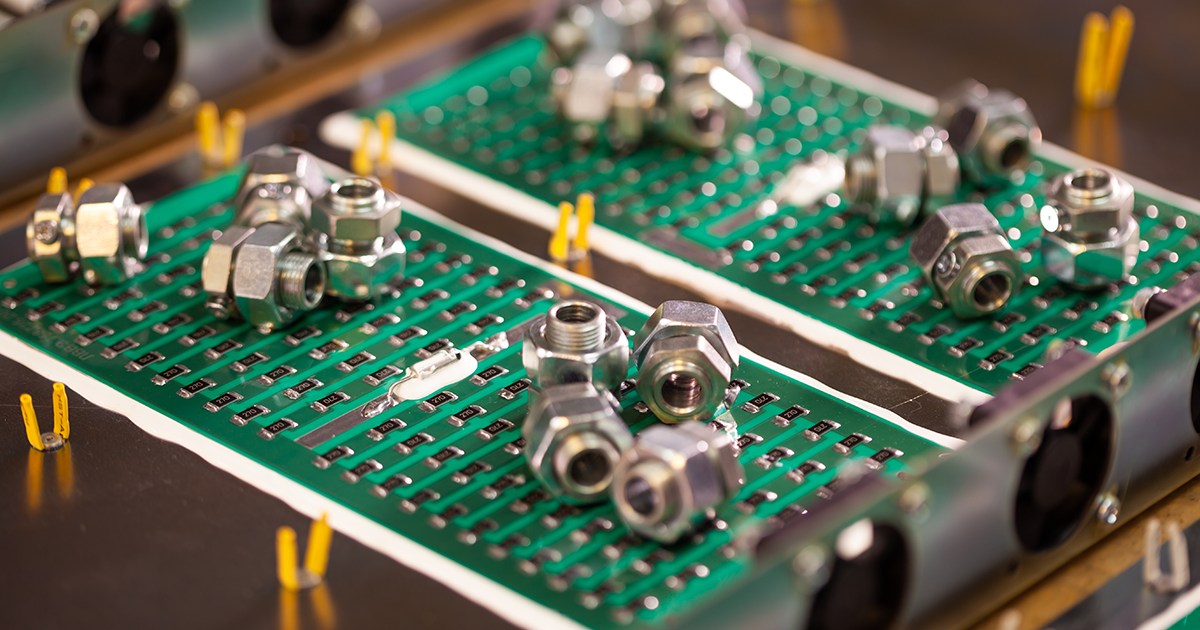

Recently, a customer in the semiconductor industry approached us with a pressing problem: their tools were wearing out too quickly. This led to frequent tool replacements, extended downtime, and soaring operational costs. For a company driven by precision and efficiency, this was a roadblock that couldn’t be ignored.

Industry Challenges: Short Tool Life, High Costs and Lost Productivity

Our customer’s existing tools struggled to keep up with the demanding requirements of machining semiconductor components.

Worn-out tools were causing:

- Frequent Tool Changes: This led to increased labour and machine downtime.

- Higher Operational Costs: Replacing tools regularly wasn’t just inconvenient—it was expensive.

- Inconsistent Performance: Short tool life affected overall efficiency and the quality of the final output.

They needed a solution that would not only last longer but also perform consistently under challenging conditions.

HPMT’s Solution: The Optimum 918DH

After assessing the challenges, we introduced the Optimum 918DH, a cutting-edge endmill specifically engineered for durability and precision in demanding applications.

Being one of HPMT’s best-selling products, the Optimum line has earned its reputation as a trusted choice among manufacturers worldwide. Its versatility and exceptional performance make it indispensable across industries such as General Machining, Mould & Die, Automotive, and Energy.

Key Features

The Tool Test: Proving the Performance

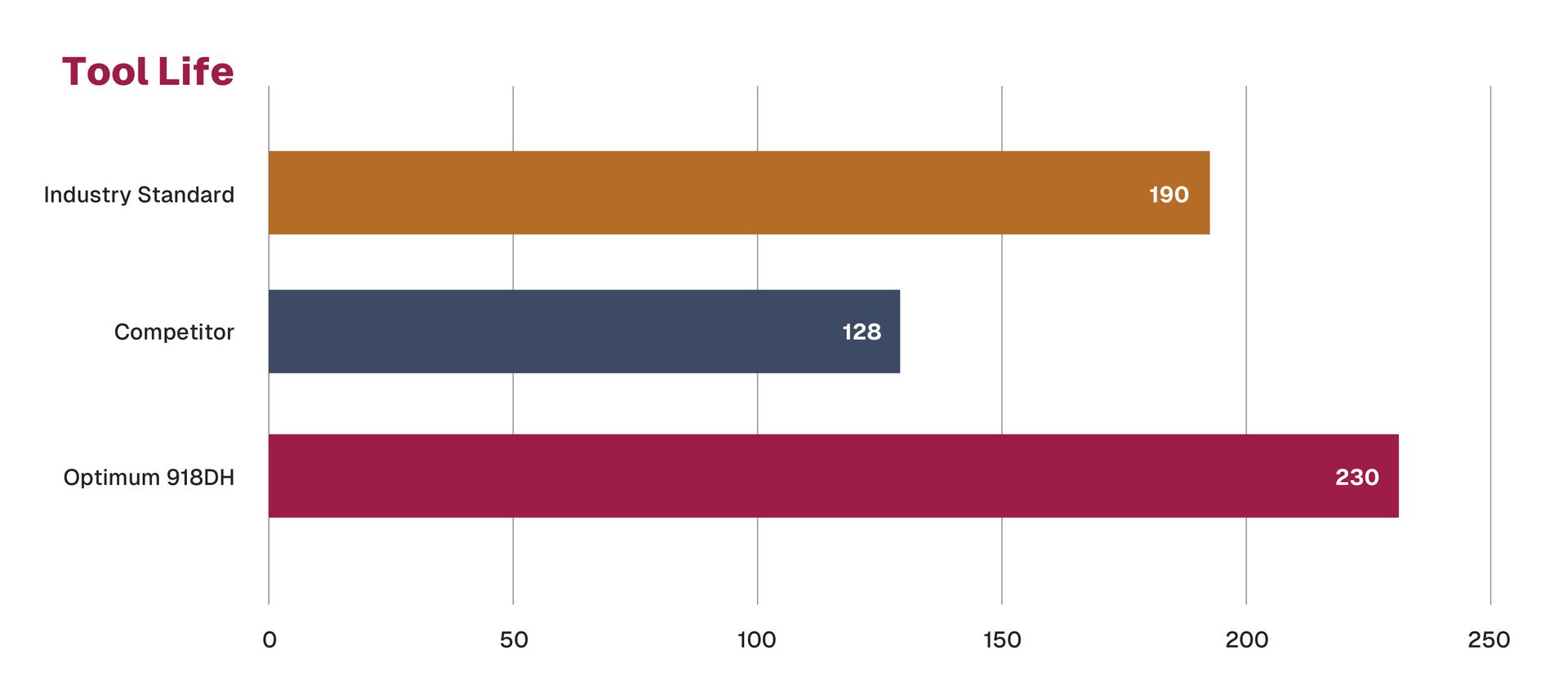

We didn’t just recommend the tool; we put Optimum 918DH to test in real-world conditions to demonstrate its effectiveness and benchmarked it against a leading competitor’s tool and the industry standard.

| Specifications |

|---|

| Endmill Diameter: 8mm |

| Workpiece: Carbon Steel S50C |

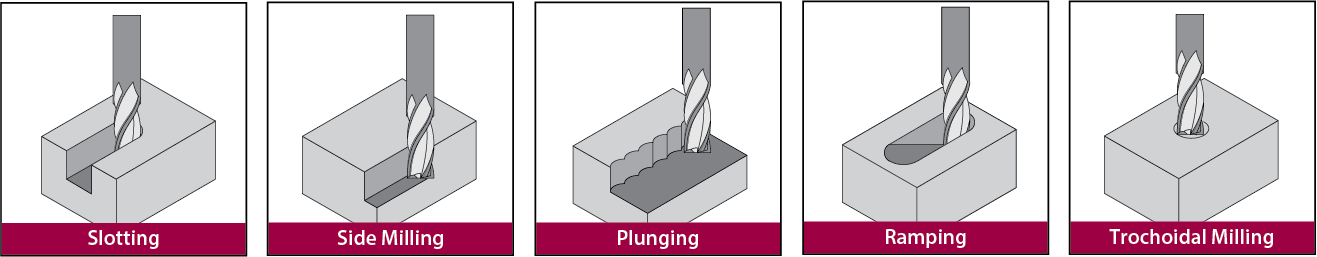

| Application Process: Side Milling |

| Cutting Data |

|---|

| Cutting speed, Vc (m/min): 100.5 |

| Feed rate, Vf (mm, min): 1200 |

| Feed per revolution, Fn: 0.3 |

| Depth of cut, Ap (mm): 15 |

| Spindle speed, n (min-1): 4000 |

| Feed/tooth, Fz:0.075 |

| Width of cut, Ae (mm): 0.5 |

Results That Speak Volumes

The Optimum 918DH exceeded expectations. Here’s how the numbers stack up:

That’s nearly double the tool life compared to the competitor and a significant edge over the industry average.

What Does This Mean for Manufacturers?

For our customer, the results translated to:

- Reduced Downtime: Fewer tool changes meant less machine stoppage.

- Lower Costs: Extended tool life cut down on replacements and labour expenses.

- Higher Efficiency: The 918DH enabled faster machining cycles without sacrificing quality.

The improved performance of the Optimum 918DH directly impacted their bottom line, making it an invaluable addition to their production process.

With features like the differential pitch and helix, a heat-resistant coating, and optimized cutting edge, the Optimum 918DH ensures that precision, durability, and cost-effectiveness are all achieved in one tool.

Versatile Applications

While this tool test focused on side milling, the Optimum 918DH is equally effective for various other machining operations and materials, including:

Materials

Applications

Ready to see what the Optimum 918DH can do for you?

Watch our tool test video below and see the difference.

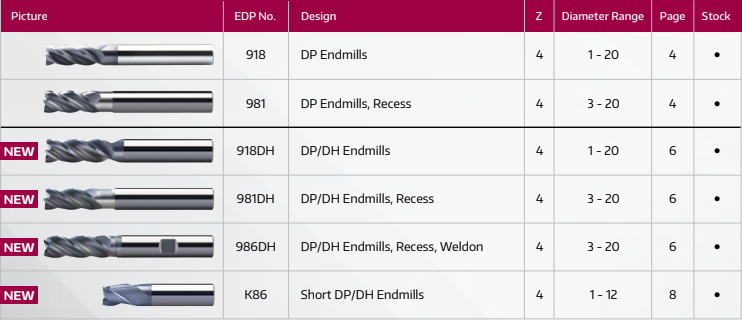

The video and the tool test results clearly demonstrate the superiority of the Optimum 918DH in terms of tool life, performance, and cost savings. This level of excellence applies across the entire Optimum Series:

Available in both Recess and Weldon options, these tools are engineered for exceptional machining versatility and reliability. Explore the full range here.

At HPMT, our mission is simple: to empower manufacturers with tools that deliver results. Contact us today to explore how the Optimum 918DH can transform your machining operations.

HPMT INDUSTRIES SDN BHD 199601032653 (405005-X)

5, Jalan Sungai Kayu Ara

32/39, Taman Berjaya,

Seksyen 32, 40460 Shah Alam,

Selangor Darul Ehsan, Malaysia

Tel: +603-58700098

Email: info@hpmt-industries.com

Our Products

Quick Link

All Rights Reserved | HPMT Industries Sdn. Bhd.