Mastering Precision: The Crucial Role of Flat Drills in Manufacturing

When it comes to precision in manufacturing, every detail matters. The ability to create precise and accurate holes is crucial in many industries, from aerospace to automotive. That's where flat drills come into play. These machining tools are specifically designed to provide precise and clean-cut holes, making them an essential tool for any manufacturing process.

Flat drills, also known as flat bottom drills are unique in their design. Unlike traditional drills that create round holes, flat drills have a flat cutting edge that produces holes with a flat bottom. This feature allows for greater precision and control, making them ideal for applications that require tight tolerances.

The importance of precision in manufacturing

Precision is the cornerstone of successful manufacturing. Whether you are creating complex machinery or intricate parts, precision ensures that everything fits together seamlessly. The slightest deviation can lead to costly errors, rework, and compromised product quality.

Flat drills play a crucial role in achieving precision in manufacturing processes. Their unique geometry allows for accurate hole placement, consistent hole diameter, and a flat bottom surface. This level of precision is essential for applications such as countersinking, spot-facing, and creating flat-bottomed holes for screws or dowels.

Advantages of using flat drills in manufacturing processes

Using flat drills in manufacturing processes offers several advantages. First and foremost, flat drills provide exceptional accuracy and precision. The flat cutting edge ensures that the resulting holes have a flat and consistent bottom, which is essential for many applications.

Another advantage of flat drills is their versatility. They can be used on a wide range of materials, including metals, plastics, and composites. This versatility makes them a valuable tool in various industries, from automotive to electronics.

Flat drills also offer efficiency in manufacturing processes. Their unique design allows for faster drilling speeds and reduces the need for additional machining operations. This not only saves time but also increases productivity and lowers production costs.

Understanding the geometry of flat drills

To fully unleash the power of flat drills, it is important to understand their geometry. Flat drills typically have a cylindrical shank, flutes, and a flat cutting edge. The number of flutes can vary depending on the drill's size and purpose. The cutting edge is ground flat, allowing for precise hole creation.

The geometry of a flat drill is carefully designed to optimize its cutting performance. The cutting edge angle, flute shape, and rake angle contribute to the drill's ability to cut through various materials. Understanding these geometrical aspects will help you select the right flat drill for your specific application and achieve the desired precision.

Choosing the right flat drill for your project

Selecting the right flat drill for your project is crucial to achieving the desired precision and efficiency. Here are some factors to consider when choosing a flat drill:

List of Services

-

Material compatibility:Item Link List Item 1

Different materials require different cutting speeds and feed rates. Consider the material you are working with and choose a flat drill that is specifically designed for that material.

-

Hole size requirements:Item Link List Item 2

Determine the size and depth of the holes you need to create. Flat drills come in various sizes and lengths, so choose one that meets your specific requirements.

-

Cutting performance:Item Link List Item 3

Look for flat drills with high-quality coatings and sharp cutting edges. These features will improve cutting performance and extend the tool's lifespan.

Flat drills stand out for its precision and versatility across multiple industries. From mould and die making to semiconductor fabrication, automotive engineering, energy production, and aerospace manufacturing, flat drills play a vital role in achieving excellence in design and production processes. With that, HPMT is pleased to introduce the

W15 flat drill. This tool boasts advanced technology and durability, ensuring precise and efficient machining operations. Learn more about its features and benefits here:

180° Point Angle Design

- Revolutionized Drilling Strategy

- Minimize the usage of pilot hole

Unique Edge Protection Design

- Enhance resistance to chipping

- Controlled burr formation on workpiece

Highly Treated Gash Surface

- Reduce friction during machining operation

- Lower machining load

- Reduce build up edge on tool

Optimized Flute Design

- High performance with excellent chip evacuation

- Resistance to chip blockage in the flute

- Low vibration machining

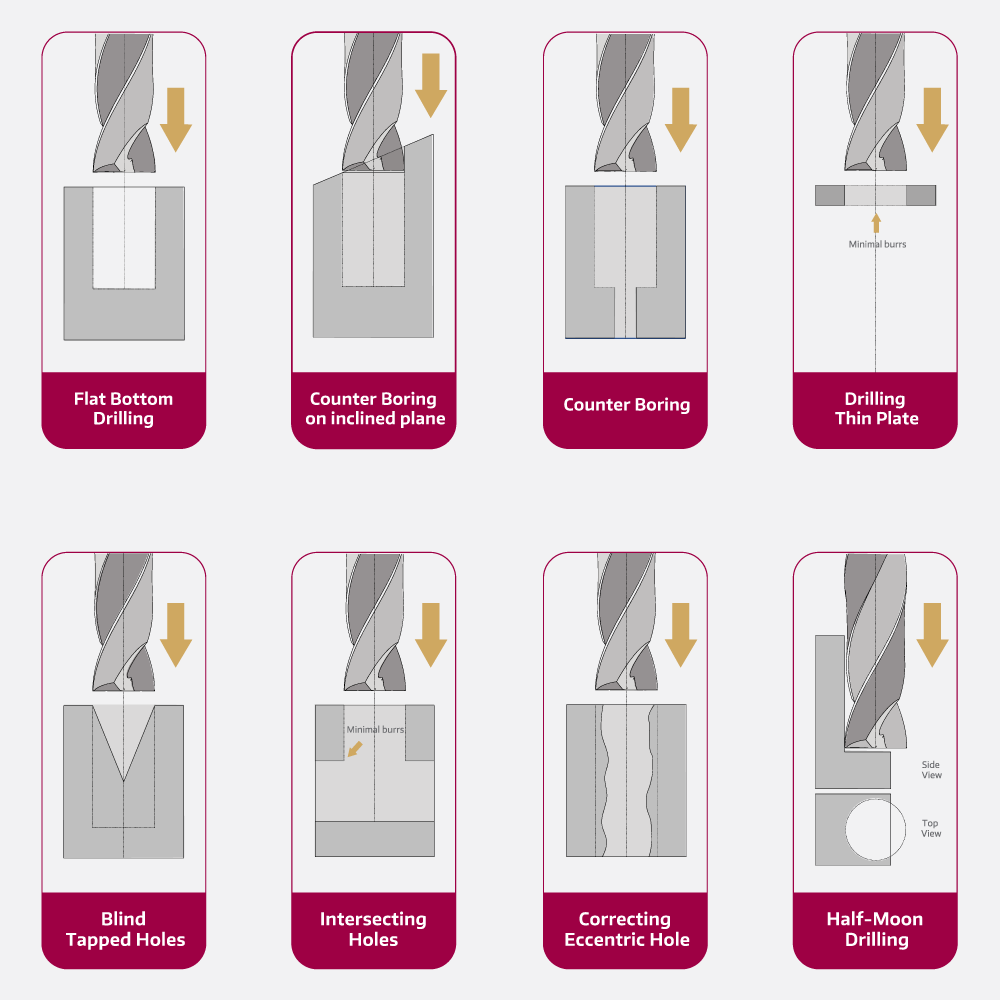

Applications of the W15 Flat Drills:

Flat drills find applications in various industries and manufacturing processes. Applications of the W15 Flat Drill include:

Mastering precision in manufacturing is a continuous journey, and the choice of tools plays a crucial role. Flat drills are an indispensable tool for achieving precision and accuracy in hole creation. Their unique design and geometry enable clean-cut, flat-bottomed holes, making them ideal for various applications. Explore HPMT's W15 flat drill

here, to elevate your machining capabilities and achieve exceptional results.

HPMT INDUSTRIES SDN BHD 199601032653 (405005-X)

5, Jalan Sungai Kayu Ara

32/39, Taman Berjaya,

Seksyen 32, 40460 Shah Alam,

Selangor Darul Ehsan, Malaysia

Tel: +603-58700098

Email: info@hpmt-industries.com

Our Products

Quick Link

All Rights Reserved | HPMT Industries Sdn. Bhd.