Drill with Coolant vs. Drill without Coolant: Which One Should You Choose?

When it comes to drilling, there are many different types of drills available. Two of the most common types are drill with coolants and drill without coolants. But which one should you choose?

Different types of drills are better suited for different materials and applications. Meanwhile, choosing the wrong drill can lead to poor results and even damage to your equipment.

In this blog article, we’ll find out what is the difference between a drill with coolant and drill without coolant and help you decide which one is right for your needs to get the most out of your drilling operations.

What is a drill with coolant?

Drills with coolant are a type of drill that uses a coolant to help lubricate and cool the drill bit as it cuts through the material. The coolant is typically delivered through the center of the drill bit and helps to reduce friction and heat buildup during the drilling process.

They are generally better suited for drilling harder materials like stainless steel or titanium. These materials tend to generate more heat during the drilling process, which can cause the drill bit to wear out more quickly. Using a coolant can help reduce heat buildup and extend the life of your drill bit.

Key Advantages

Drills with coolant are a type of drill that uses a coolant to help lubricate and cool the drill bit as it cuts through the material. There are several key advantages to using a drill with coolant over a drill without coolant:

List of Services

-

- Extend tool lifeItem Link List Item 1

First and foremost, drills with coolant are better suited for drilling harder materials like stainless steel or titanium. These materials tend to generate more heat during the drilling process, which can cause the drill bit to wear out more quickly. By using a coolant, you can help reduce heat buildup and extend the life of your drill bit.

-

- Improved work qualityItem Link List Item 2

In addition to extending the life of your drill bit, using a coolant can also help to improve the quality of your work. You can ensure that your holes are clean and precise by reducing friction and heat buildup during the drilling process.

-

- Reduced downtimeItem Link List Item 3

Using a coolant can also help to improve your efficiency and productivity. By reducing heat buildup and extending the life of your drill bit, you can reduce downtime and increase your throughput.

-

- Lessened frictionItem Link List Item 4

Friction can cause rough edges and problems in the material you're drilling. It might also damage the drill bits or tools. Therefore, using the fluid can help to reduce friction and heat buildup during the drilling process, which can cause the drill bit to wear out more quickly.

Coolant Situation During Drilling

Drilling Depth:

- ≤ 5 × Ø; External Flood Coolant minimum of 8 bar.

- 3 × Ø; Internal through coolant minimum of 8 bar is recommended for optimum result.

- 5 × Ø; Internal through coolant 12 bar

- 12 × Ø; Internal through coolant of at least 40 bar is highly recommended.

- Dry drilling should be avoided as it will shorten the tool’s life significantly.

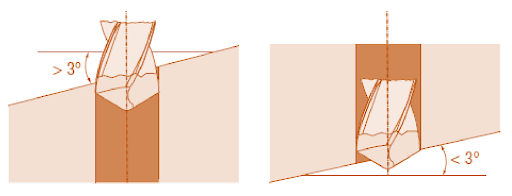

Maximum entry and exit angle

Image Credits:

HPMT Drilling Handbook

Entering non-flat surfaces

When going into non-flat surfaces, there is a danger of drill deflection. To avoid this, the feed can be reduced when entering.

- Convex surface: No feed reduction is necessary.

- Concave surface: Reduce to 33% of the original feed rate.

- Inclined surface: Reduce to 33% of the original feed rate.

- Curved surface: Reduce to 33% of the original feed rate.

What is a drill without coolant?

A type of drill that does not use any coolant during the drilling process. Instead, it relies on the friction generated by the drill bit as it cuts through the material to help remove chips and debris.

Drills without coolant are generally less expensive than drills with coolant and are better suited for softer materials like aluminum or wood. Because these materials generate less heat during the drilling process, there is less need for a coolant to help reduce friction and heat buildup.

Key Advantages

Drills without coolant are generally less expensive than drills with coolant and are better suited for softer materials like aluminum or wood. Here are some important advantages of drill without coolants:

List of Services

-

- Generates less heatItem Link List Item 1

Because these materials generate less heat during the drilling process, there is less need for a coolant to help reduce friction and heat buildup.

-

- Easier to useItem Link List Item 2

In addition to being more affordable, drills without coolant are also easier to use than drills with coolant. They are simpler to set up and use, making them ideal for DIY projects and other applications where ease of use is important.

-

- More versatileItem Link List Item 3

Finally, they are also more versatile than drill with coolants. Because they can be used on a wider range of materials, they are ideal for a variety of applications and can be used for everything from woodworking to metalworking.

Selecting the Right Drill for You

When it comes to

coolant vs without coolants, you need to select the right drill for your needs. Here are some of the several factors to consider:

List of Services

-

- Material and ApplicationItem Link List Item 1

The type of material you’ll be drilling is one of the most important factors to consider when choosing between coolant and drill without coolants.

If you’re working with softer materials like aluminum or wood, then a drill without coolant may be sufficient. However, a drill with coolant may be your best bet if you’re working with harder materials like stainless steel or titanium.

-

- Precision and Tool LongevityItem Link List Item 2

Another factor to consider is the precision and longevity you require from your tools. drills with coolant are generally better suited for drilling harder materials like stainless steel or titanium.

It’s because they help to reduce heat buildup and extend the life of your drill bit. However, if you’re looking for precision over longevity, then drills without coolant may be sufficient.

-

- Project ScaleItem Link List Item 3

Finally, they are also more versatile than drill with coolants. Because they can be used on a wider range of materials, they are ideal for a variety of applications and can be used for everything from woodworking to metalworking.

-

- Budget and MaintenanceItem Link

Finally, you should also consider your budget and maintenance needs when choosing between drill with coolant and drill without coolants.

Drills with coolant are generally more expensive than drills without coolant, so if you’re on a tight budget then a drill without coolant may be your best bet. Additionally, drills with coolant require more maintenance than drills without coolant because they use a coolant during drilling.

HPMT offers a

wide range of high-quality solid carbide drills, including NC spotting drills, twist drills, oil feed twist drills, spiral burnishing drills, long drills, and more, catering to your industry-specific requirements.

Conclusion

Should I buy a drill with coolant? Both drill with coolants and drill without coolants have their own unique strengths and weaknesses. When choosing between the two, it’s important to consider the type of material you’ll be drilling, the precision and longevity you require from your tools, the scale of your project, and your budget and maintenance needs. Therefore, it’s not to say that one drill is better than another in all instances; it depends on the task at hand.

HPMT is committed to providing high-quality cutting tools and services to clients worldwide.

Contact us today to learn more about

our products and services.

HPMT INDUSTRIES SDN BHD 199601032653 (405005-X)

5, Jalan Sungai Kayu Ara

32/39, Taman Berjaya,

Seksyen 32, 40460 Shah Alam,

Selangor Darul Ehsan, Malaysia

Tel: +603-58700098

Email: info@hpmt-industries.com

Our Products

Quick Link

All Rights Reserved | HPMT Industries Sdn. Bhd.