Mastering Small Part CNC Machining: Overcoming Common Challenges and Solutions

In small part machining, the complexity lies in the intricate geometries and microscopic dimensions of the components. Achieving the desired precision and accuracy requires specialized equipment , tooling, and technique. With advanced technology and high-quality cutting tools from companies such as HPMT, most CNC machines have become highly adjustable in producing highly complex small parts.

Despite the flexibility of small part machining, certain challenges remain. In the following sections, we will explore the common challenges encountered in small part CNC machining and provide practical solutions to overcome them.

Precision and Tolerance

Challenge: Achieving the required level of precision and tight tolerances is paramount in small part machining. The miniature size of the components magnifies the impact of even the slightest deviation, potentially compromising functionality and fit within larger assemblies. The tight tolerance required for these parts means that any errors in the machining process can have an insightful impact on the final product.

Solution: Advanced CNC machines with high-precision capabilities should be used to address this challenge. Additionally, meticulous tool selection, careful programming, and close monitoring of machining parameters are essential. Implementing rigorous quality control processes, such as in-process inspections and post-machining measurements, can help ensure adherence to specified tolerances.

Surface Finish

Challenge: A high-quality surface finish is crucial, especially in manufacturing industries. However, small part machining can present challenges in achieving the desired surface finish due to the intricacies of removing material at such a small scale.

Solution: To improve surface finish, selecting cutting tools designed specifically for small part machining is important. Implementing techniques such as high-speed machining, fine-step milling, or micro-milling can help achieve smoother surfaces. Optimizing cutting parameters, controlling coolant flow, and employing appropriate toolpath strategies can further enhance surface finish.

HPMT recommends cutting parameter that can help you determine the optimal settings for your tools based on the material and machining conditions.

Chip Evacuation

Challenge: Due to limited space and chip size, effective chip evacuation becomes more challenging in small part machining. Inadequate chip evacuation can cause chip recutting, poor surface finish, and tool damage.

Solution: Collaboration with experienced engineers and designers, such as those at HPMT, can help optimize the design for manufacturability. Simplifying complex geometries, adjusting tolerances, and selecting appropriate machining techniques can aid in achieving tight tolerances. Conducting thorough feasibility studies and prototype testing can provide valuable insights into achieving desired tolerances while maintaining functionality.

Material Damage

Challenge: Machining small parts can lead to thermal and mechanical damage to the material due to the smaller size and limited material surrounding the cut area. This problem can result in higher temperatures and increased chances of damage.

Solution: Minimizing material damage requires carefully selecting cutting tools, cutting parameters, and coolant application. Implementing techniques such as high-speed machining, utilizing advanced tool coatings, and optimizing cutting strategies can help reduce heat generation and mitigate the risk of material damage. Additionally, selecting materials with better machinability characteristics and ensuring proper workpiece fixturing can further minimize the chances of damage.

By implementing these solutions, manufacturers can overcome the common challenges in small part machining, improve productivity, and achieve high-quality results. With the right techniques and tools, small part machining can become a streamlined and efficient process, ensuring the successful manufacturing of miniature components.

Explore HPMT's wide selection of micro cutting tools to find the perfect match for your machining and industry needs.

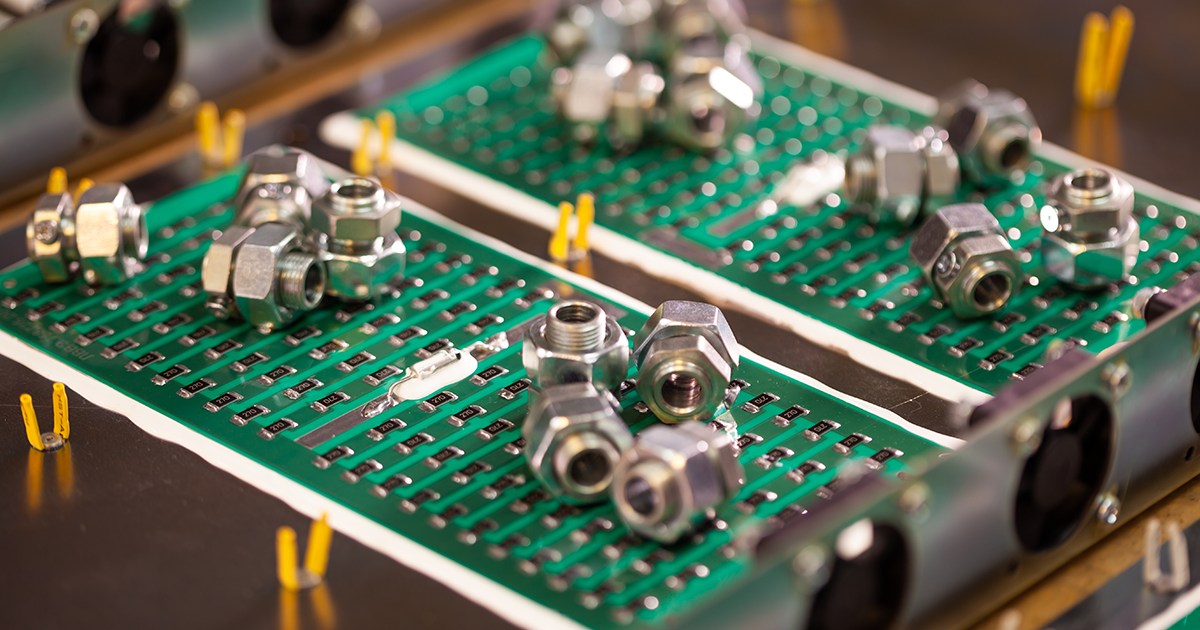

Applications of Small Part Machining

Small part machining finds applications across diverse industries, including aerospace, electronics, medical devices, and automotive. In the aerospace sector, it enables the production of miniature turbines, fuel injectors, and complex engine components. Electronics manufacturing relies on small part machining for microchips, connectors, and miniature sensors. Precision small part machining is essential in producing surgical instruments and implants for the medical field. The automotive industry can benefit from small part machining through its usage in fuel injection systems, sensors, and intricate engine components. These applications emphasize the pivotal role of small part machining in advancing technology and enabling innovation.

Conclusion

Are you ready to harness the power of small part machining? By embracing small part machining, you can stay at the forefront of your industry, drive innovation, and meet the ever-growing demand for miniature components.

Work together with HPMT engineers to produce the desired parts with precision. Our team of experts understands the intricacies of small part manufacturing and can help you unlock new possibilities. Contact us today to learn more about our products and services.

HPMT INDUSTRIES SDN BHD 199601032653 (405005-X)

5, Jalan Sungai Kayu Ara

32/39, Taman Berjaya,

Seksyen 32, 40460 Shah Alam,

Selangor Darul Ehsan, Malaysia

Tel: +603-58700098

Email: info@hpmt-industries.com

Our Products

Quick Link

All Rights Reserved | HPMT Industries Sdn. Bhd.